Manufacturing

Emilie GooPlus2025-09-12T12:18:46+02:00Manufacturing

100% French artisanal production

A French manufacturer

NICOLLE® chairs benefit from a long tradition of artisanal manufacturing, built over a century with industrial expertise and using durable, highly resistant materials. durables et très résistants.

This experience guarantees the quality, solidity and originality of our products.

The metal is sourced from local French suppliers. Its hardness and strength are meticulously controlled.

The seat

All parts are manufactured from flat sheets and coils of strip steel

They are then shaped using the stamping technique.

Since 2020, the laser cutting technique has been introduced, allowing material savings and a certain time gain.

The metal seat of Nicolle® chairs and stools is stamped on a press exerting a pressure of 125 tonnes from a laser-cut metal disc perforated at its center.

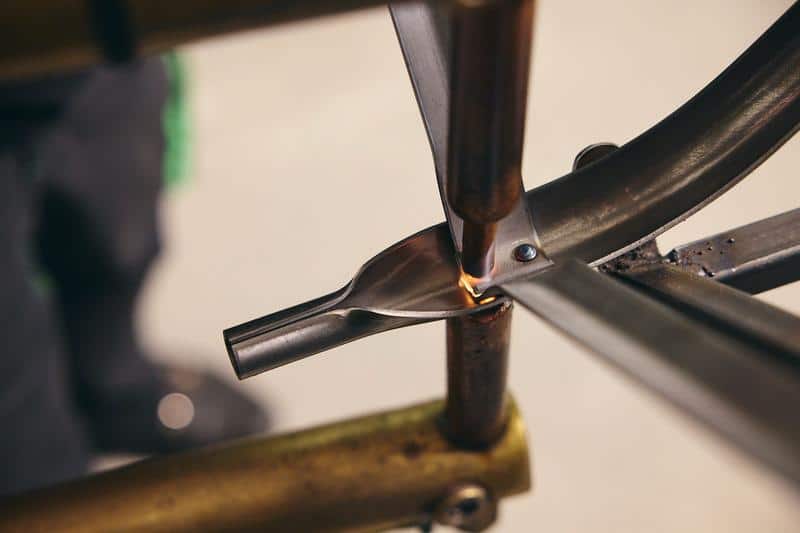

The backrest and its swan neck

The famous Nicolle® backrest, also called a whale tail, is shaped under 80 tonnes of pressure.

The swan neck, which connects the seat to the backrest, first undergoes pre-bending on an 80-tonne press, before being stamped on a 125-tonne press.

The 2 parts making up the backrest are then assembled by spot welding.

Foot shaping

The legs are made from strip metal, a coil of flat steel,

The first step is to unroll the strip and cut the “flanks”. These are cut to different lengths depending on the type of feet (45–60 – 65 – 75 – 80 cm).

Then, a first fold is executed on a 60-tonne COFMO press.

Then the feet must be punched at both ends to accommodate the future stretcher.

The punching is done on a small 30-ton press.

Stamping on a 125-tonne press gives the leg its shape.

A trimming is carried out at the top of the foot using a small 30-tonne press in order to round it perfectly.

Finally, each foot is rolled on a 15-tonne press to accommodate the rubber pad.

It therefore takes 7 passes, requiring human intervention, to shape a Nicolle® chair or stool leg!

Shaping the stretchers

The stretchers are the horizontal pieces that connect the legs together. They ensure the rigidity of the seat.

There are 4 stretchers per stool or chair, 3 smooth and one stamped Nicolle.

Still using strip metal, we start by cutting sides of various lengths for the different stretchers.

Then we punch each side so that the feet can be riveted.

The flat piece is then stamped on a 60-tonne press which will bend it and give it its shape while stiffening it.

Two operations are necessary, on the left and on the right, to give the final shape to the two sides of the stretcher.

5 passes are therefore necessary to produce these essential parts for all our seats.

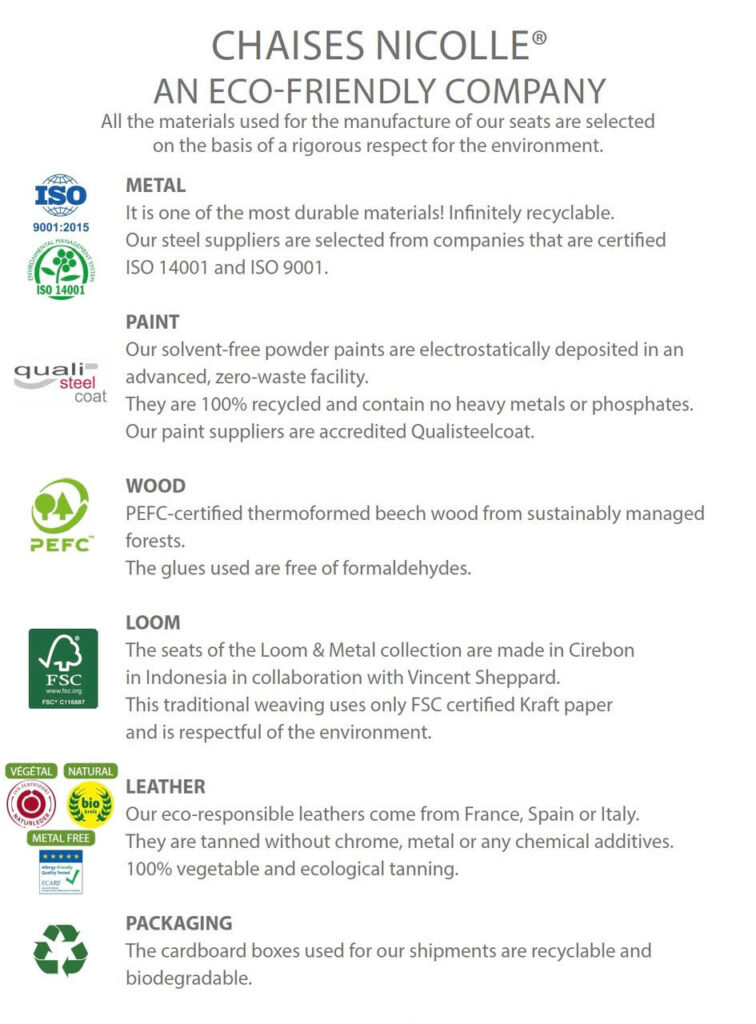

Preparation before painting

Preparation before painting is essential because the quality of the finish is determined by the following series of operations.

The seats are first degreased at very high temperature and then dried.

Sanding will remove any roughness or defects in the sheet metal. The process will vary depending on the finish. For example, welding points will be slightly reduced for painted finishes, while for varnished finishes they will remain more visible.

The last step consists in wiping and blowing off the dust.

Paint

The raw seats are then delivered to a painter who will take care of the epoxy powder coating.

Suspended on a chain, the various spare parts of the Nicolle® chairs will be covered with electrostatic powder and then placed in an oven heated to 180°C.

This ecological coating ensures a uniform, durable finish and guarantees very good resistance to wear.

Our chairs and stools are therefore customisable with over 200 colors from the RAL K7 color chart.

This solvent-free epoxy powder coating is 100% recyclable.

Our suppliers have a “high-performance” facility with no discharges, heavy metals, or phosphates. They are Qualisteelcoat certified.

Quality control, packaging and delivery

After painting, the chairs and stools are meticulously inspected before the rubber feet are fitted.

All our seats are tested on flat surface to ensure perfect stability.

We then carry out high-quality packaging to guarantee that our seats reach their destination in perfect condition, in France and worldwide.

The boxes used for our shipments are recyclable and biodegradable.

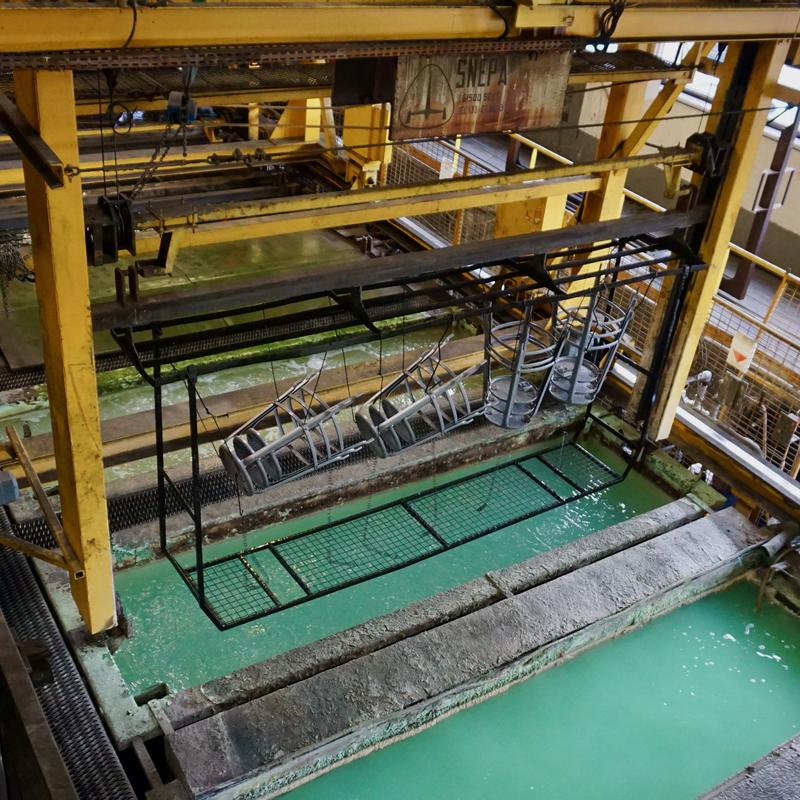

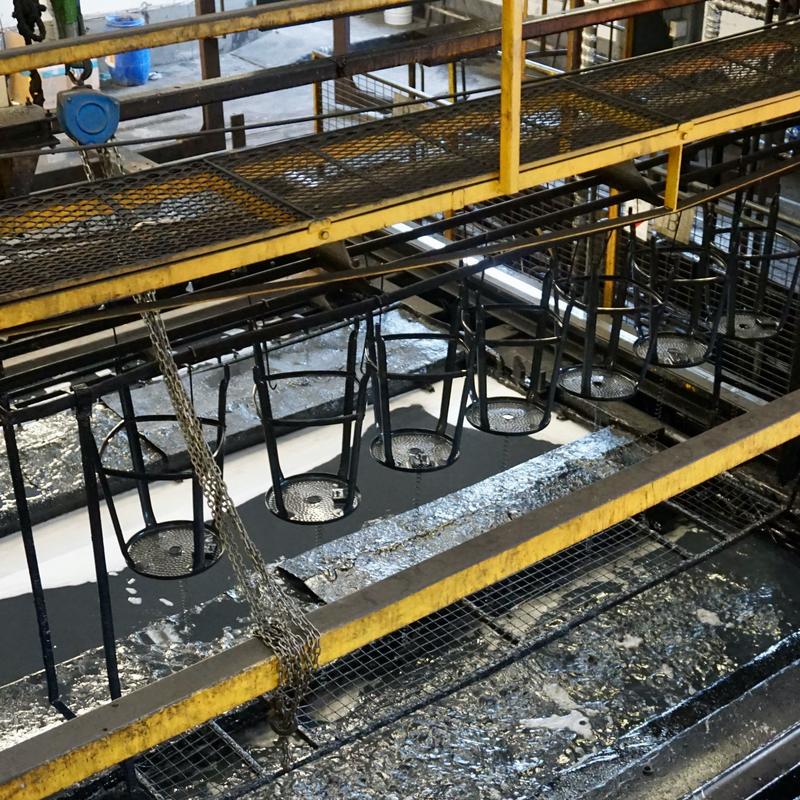

Nicolle ® “Outdoor” chairs and stools are treated by cataphoresis.

Nicolle ® “Outdoor” chairs and stools are treated by cataphoresis.

This technique, widely used by the automotive and aeronautical industries, consists in electrochemically depositing an epoxy base on a metal part.

The Nicolle® outdoor seats are immersed in several baths of stripping, degreasing, phosphating and then water-soluble paint. The 20 to 40-micron paint layer penetrates evenly into all the parts, including the hidden areas.

The treated parts turn black, making impossible to apply transparent or tinted varnishes.

The seats are then powder-coated with epoxy and baked at 180°C.

Chairs and stools treated this way can effectively resist oxidation, even by the seaside.

Salty sea fog or morning dew will no longer damage these seats, significantly extending their lifespan.